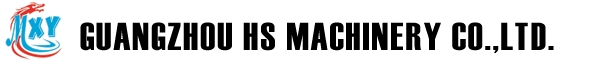

Standard units

1) Automatic Belt suction feeder;

2) Pre-creaser and creaser (3,5ply);

3) Wheel gluing system;

4) Up folding beams with auto correction device for fishtail problem;

5) Squaring device;

6) Counter Ejector;

7) Motorized adjustment system;

Technical parameters

|

Model |

AFG-M-1200x2000 |

AFG-M-1200x2400 |

|

Power consumption(Voltage, HZ) |

380V or 415 V, 50HZ, 3 phase |

380V or 415 V, 50HZ, 3 phase |

|

Max. carton box (L x W) |

500x500x500x500 |

600x600x600x600 |

|

Min. carton box (L x W) |

120x120x120x120(mini beam) |

120x120x120x120 mini beam |

|

200x200x200x200(big beam) |

200x200x200x200(big beam) |

|

|

Paperboard thickness |

2-9mm |

2-9mm |

|

Glue width |

45mm |

45mm |

|

Feeding mode |

Suction belt feeding |

Suction belt feeding |

|

Max. paperboard (L x W) |

1200x2400 mm |

1200x2400 mm |

|

Min. paperboard (L x W) |

250x550mm (mini beam) 300x800 mm ( big beam) |

250x550mm (mini beam) 300x800 mm (big beam) |

|

Forming mode |

Up folding |

Up folding |

|

Total power (KW) |

12 |

12 |

|

Working speed pcs/min |

80-150 (by size and quality) |

80-150(by size and quality) |

|

Machine dimension |

8000x2800x1100 |

8000x3500x1100 |

Functions descriptions:

A.Automatic belt suction feeder

1. Manual adjustment of left/right board and front gate gap.

2. Second pre-creasing and creasing unit.

3. Motorized adjustment of roller gaps.

B. Wheel gluing unit

Wheel-gluing system. Gluing tank can be motorized adjustment to left and right direction.

C. Up folding unit

1.Main folding belt is imported from Italy, high quality, durable.

2.Upward folding avoids glue flow to the ground.

3.Motorized movement of the left/right folding beams.

4.Side guide device on both folding beams to make the creased paperboards go straightly in a linear way;

5.There seated auto correction mechanism on the folding beam to remedy the fishtail problems.

D.Squaring unit

1. To square all the folded cartons for an acceptable accuracy.

2. To count the quantity of the passing cartons.

E.Counter Ejector

Bundles will be automatically ejected out when reached a certain quantity.

F.Consumable parts:

photocell sensor, belts

G.Sources of main parts

a. Main motor Taiwan Debang

b. Main electrical parts Sneider

c. Main bearings Japan

d. Main belts Italy and Korea